HVLS Fans

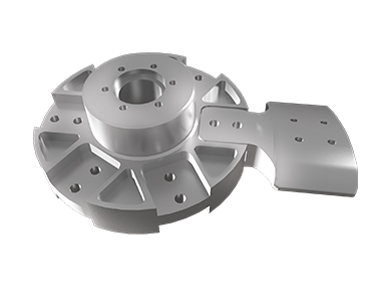

Permanent Magnet Direct Drive

Large ceiling fans are also known as: industrial large ceiling fans, industrial fans, and HVLS fans.

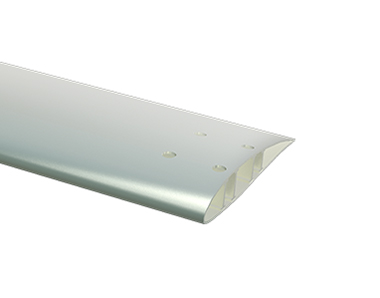

1. HVLS fan has low speed, large air volume, large radiation range, the maximum diameter of the fan blade is 7.3M, the coverage area is approximately equal to the coverage area of 50 0.75M small fans, the maximum air volume is 13100m³/MIN, the coverage area is 1500㎡, and the power is only 1.5KW

2. Personnel cooling: The natural breeze generated by the HVLS fan blows on the human body, promotes the evaporation of sweat and takes away the body heat, cooling the human body and bringing a comfortable and cool feeling.

3. Natural ventilation: The large radiation range of HVLS fans effectively enhances the orderly movement of airflow in the space, promotes air mixing throughout the space, and cooperates with negative pressure fans to achieve better natural ventilation and cooling effects.

4. Dehumidification and dehumidification: At present, warehouses mainly use pallet loading, carton packaging, etc. When the air humidity is high, it is easy to cause problems such as cartons deterioration and softness, pallet pallets being damp and deformed, and the ground being slippery. The use of HVLS fans can solve the problem.

5. Installation conditions: H-shaped steel, I-beam, steel-concrete square beam, ball column and other structures are acceptable. The building height is required to be greater than 4.5M, and the minimum safety distance between the fan blades and obstacles is not less than 0.2M.

6. Application occasions: widely used in industrial plants, logistics warehousing, waiting rooms, exhibition halls, gymnasiums, supermarkets and other tall spaces.

Customer Service

+86 181-5957-1206

Home

Home Products

Products Telephone

Telephone Message

Message